Igwe ọkụ ọkụ dị ala voltaji

Ngwa

1.Jiri maka obere voltaji

2.Protection megide mmiri na nrụgide

3.Suitable maka nkwụsị USB na nchebe mkpuchi mkpuchi nke etiti

Njirimara

1.Excellent corrosion eguzogide

2.UV mgbochi na iguzogide ihu igwe

3. Halogen-free

4.Superior eletriki na akụrụngwa akụrụngwa.

Mmepụta nke ikpo ọkụ na-ekpo ọkụ ga-ebu ụzọ họrọ masterbatch kwesịrị ekwesị, wee họrọ ihe inyeaka iji mepụta kpọmkwem.

Ihe mkpuchi ụlọ thermal.

1. The mmepụta usoro nke okpomọkụ shrinkable tube bụ nke mbụ mmepụta nke polyene leech masterbatch: ijikọta ihe dị iche iche polyene leech isi ihe dị iche iche na-arụ ọrụ inyeaka ihe.

A na-atụnye ihe ndị ahụ dị ka usoro usoro ahụ si dị wee gwakọta ya: a na-etinye ihe ndị a gwakọtara n'ime ihe ejima ejima na pelletized iji mepụta polyene leech na-arụ ọrụ masterbatch.

2. Usoro ịkpụzi ngwaahịa: dị ka ọdịdị nke ngwaahịa ahụ si dị, a pụrụ iji ụzọ abụọ nke otu ịghasa extrusion na injection ịkpụzi.

Maka nhazi na mmepụta:

1. Single-ịghasa extrusion ụdị: tumadi eji extrusion ịkpụzi nke okpomọkụ sink ọkpọkọ, dị ka otu mgbidi okpomọkụ-shrinkable tubes, okpukpu abụọ-mgbidi okpomọkụ-shrinkable tubes na gluu, na ọkara ọkpụrụkpụ.

Ọkpụkpọ ọkpọkọ ọkụ na-ekpo ọkụ mgbidi, ọkpọkọ ikuku ikuku busbar dị elu, ọkpọkọ okpomoku okpomoku dị elu na ngwaahịa ndị ọzọ na-ahazi ma guzobe site na otu ịghasa extrusion.

The okpomọkụ shrinkable tube mmepụta akara kwesịrị inwe ndị na-esonụ ngwá: extruder (okpomọkụ tube akpụ), mmepụta ebu, jụrụ mmiri tank, esemokwu ngwaọrụ, na

Ngwa diski, wdg.

2. Injection ịkpụzi: tumadi eji maka mmepụta nke okpomọkụ-shrinkable akụkụ pụrụ iche ekara, dị ka okpomọkụ sink okpu, okpomọkụ-shrinkable nche anwụ sket, okpomọkụ-shrinkable mkpịsị mkpịsị aka na ngwaahịa ndị ọzọ.

Ha niile na-eji ịkpụzi injection, na akụrụngwa mmepụta kwesịrị ịgụnye igwe na-akpụzi injection na ihe ntụtụ.

3. Nzọụkwụ ọzọ dị mkpa bụ radieshon cross-linking.Ngwaahịa ndị a na-emepụta site na extrusion ma ọ bụ ịkpụzi injection ka bụ usoro molekụla ahịrị.

Ihe owuwu, ngwaahịa ahụ enwebeghị "ọrụ nchekwa", na arụmọrụ nke nguzogide okpomọkụ, ịka nká, na nguzogide eyi ezughị.

Gbanwee usoro ihe omimi nke ngwaahịa.Usoro anyị na-ejikarị bụ mgbanwe mgbanwe nke radieshon: electron accelerator radieshon crosslinking, cobalt source radieshon.

Cross-linking, peroxide kemịkalụ cross-linking, n'oge a molekul na-agbanwe site a linear molekul Ọdịdị na a netwọk Ọdịdị.Ngwaahịa ndị extruded na-agafe

Mgbe njikọ gafere, ọ nwere "mmetụta nchekwa", nke na-eme ka nguzogide okpomọkụ dị ukwuu, ihe ndị na-emepụta ihe, na ihe ndị dị na kemịkal nke tube ọkụ na-ekpo ọkụ.The kpọmkwem table

Ugbu a tube sink okpomọkụ agbanweela site na ọnọdụ nke nnabata na-ekwekọghị ekwekọ, nguzogide ịka nká, nguzogide abrasion, na nguzogide corrosion kemịkalụ.

4. Mgbasawanye ịkpụzi: Ngwaahịa a gbanwere site na radieshon crosslinking enweelarị "mmetụta ebe nchekwa ọdịdị", ọ nwekwara nnukwu elu.

Ọrụ adịghị agbaze n'okpuru okpomọkụ.Mgbe kpo oku na elu okpomọkụ, agụụ ịfụ na jụrụ, ọ na-aghọ okokụre okpomọkụ shrinkable tube, na mgbe ahụ dị ka tube si kwuo.

Ọnọdụ n'ezie nke nkwakọ ngwaahịa ngwaahịa na mmechi nwekwara ike ịkpụ ma bipụta dịka mkpa ndị ahịa si dị.Ngwunye nkịtị na-anọpụ iche dịkwa.

Arụmọrụ

| Nwalee | Usoro ule | Ihe achọrọ |

| Ọnọdụ okpomọkụ na-arụ ọrụ | UL 224 | -50 ruo +125 ℃ |

| Ike ọdụdọ | ASTM D2671 | ≥14 Mpa |

| Elongation na ezumike | ASTM D2671 | :400% |

| elongation na nkwụsịtụ mgbe okpomọkụ ịka nká | ASTM D 2671 158℃/168h | ≥300% |

| Ogologo mbelata | UL 224 | 0±5% |

| Ọnụego mgbidi akụkụ | ASTM D2671 | 30% |

| Ịkwụsị ire ọkụ | VW-1 | Gafe |

| Olu resistivity | IEC 93 | 1014Ω.m |

| Nkwụsi ike ọla kọpa | UL224 | Gafe |

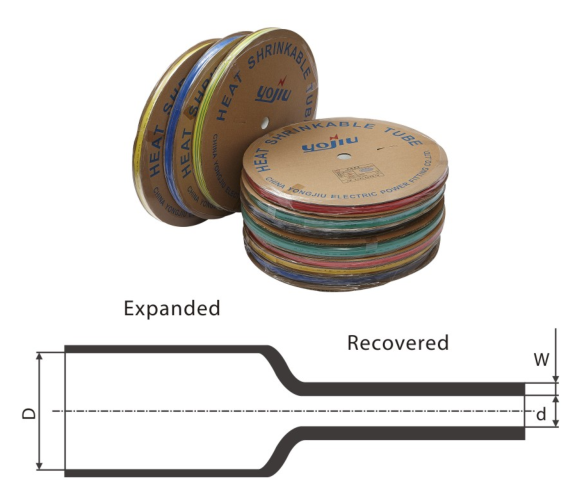

| Ụdị | NJ agbadoro (mm) ±0.1 | NJ eweghachitere (mm) | Ọkpụrụkpụ Mgbidi eweghachitere (mm) ±0.05 | Ogologo(mm) |

| ZRG-1.0/0.5 | 0.4 | > 1.4 | 0.4 | 400 |

| ZRG-1.5/0.75 | 0.6 | > 1.9 | 0.4 | 300 |

| ZRG-2.0/10 | 0.9 | > 2.4 | 0.45 | 200 |

| ZRG-2.5/125 | 1.1 | > 2.9 | 0.45 | 200 |

| ZRG-3.0/15 | 1.4 | > 3.4 | 0.45 | 200 |

| ZRG-3.5/1.75 | 1.6 | > 3.9 | 0.45 | 200 |

| ZRG-4.0/2.0 | 1.8 | > 4.4 | 0.45 | 100 |

| ZRG-5.0/2.5 | 2.3 | > 5.3 | 0,50 | 100 |

| ZRG-6.0/3.0 | 2.8 | > 6.3 | 0,50 | 100 |

| ZRG-7.0/3.5 | 3.3 | > 7.4 | 0.55 | 100 |

| ZRG-8.0/40 | 3.8 | > 8.4 | 0.55 | 50 |

| ZRG-9.0/45 | 4.3 | > 9.4 | 0.55 | 50 |

| ZRG-10.0/5.0 | 4.8 | > 10.4 | 0.55 | 50 |

| ZRG-11.0/5.5 | 5.3 | > 11.4 | 0.60 | 50 |

| ZRG-12.0/6.0 | 5.7 | > 12.4 | 0.60 | 50 |

| ZRG-13.0/6.5 | 6.2 | > 13.4 | 0.60 | 50 |

| ZRG-14.0/7.0 | 6.7 | > 14.4 | 0.60 | 50 |

| ZRG-15.0/7.5 | 7.2 | > 15.5 | 0.65 | 50 |

| ZRG-16.0/8.0 | 7.7 | > 1.65 | 0.65 | 25 |

| ZRG-17.0/8.5 | 8.2 | > 17.5 | 0.7 | 25 |

| ZRG-18.0 / 9.0 | 8.7 | > 19.0 | 0.80 | 25 |

| ZRG-20.0/10.0 | 9.7 | > 21.0 | 0.90 | 25 |

| ZRG-22.0/11.0 | 10.0 | > 22.0 | 0.90 | 25 |

| ZRG-250/12.5 | 11.0 | > 25.0 | 0.90 | 25 |

| ZRG-28 0/14.0 | 13.0 | > 280 | 0.90 | 25 |

| ZRG-30.0/15.0 | 14.0 | > 30.0 | 1.00 | 25 |

| ZRG-35.0/17.5 | 16.0 | > 35.0 | 1.00 | 25 |

| ZRG-40.0/20.0 | 19.0 | > 42.0 | 1.00 | 25 |

| ZRG-50.0/25.0 | 24.0 | > 500 | 1.00 | 25 |

| ZRG-60.0/30.0 | 30.0 | > 60.0 | 1.00 | 25 |

| ZRG-70.0/35.0 | 35.0 | > 70.0 | 1.10 | 25 |

| ZRG-80.0/40.0 | 40.0 | > 80.0 | 1.10 | 25 |

| ZRG-90.0/45.0 | 45.0 | > 90.0 | 1.20 | 25 |

| ZRG-100.0/50.0 | 50.0 | > 100.0 | 1.20 | 25 |

| ZRG-120.0/6 0.0 | 60.0 | > 120.0 | 1.20 | 25 |

| ZRG-150.0/75.0 | 75.0 | > 150.0 | 1.20 | 25 |

| ZRG-200.0/100.0 | 100.0 | > 200.0 | 1.20 | 25 |

Ajụjụ: Ị nwere ike inyere anyị aka ibubata na mbupu?

Ajụjụ: Ị nwere ike inyere anyị aka ibubata na mbupu?

A: Anyị ga-enwe otu ọkachamara ga-ejere gị ozi.

Ajụjụ: Gịnị bụ asambodo ị nwere?

A: Anyị nwere asambodo nke ISO, CE, BV, SGS.

Ajụjụ: Gịnị bụ oge ikike gị?

A:1 afọ n'ozuzu.

Q: Ị nwere ike ịrụ ọrụ OEM?

A: EE, anyị nwere ike.

Ajụjụ: Kedu ihe ị na-edu oge?

A: Anyị ọkọlọtọ ụdị bụ na ngwaahịa, dị ka nnukwu iwu, ọ na-ewe banyere 15 ụbọchị.

Ajụjụ: Ị nwere ike ịnye samples efu?

A: Ee, biko kpọtụrụ anyị ka anyị mara ụkpụrụ ụkpụrụ.